100% Recycled

Completely Replaces Virgin Plastic Fibres or Steel Reinforcing Mesh

An Australian innovation, eMesh recycles plastic to deliver innovative reinforced concrete.

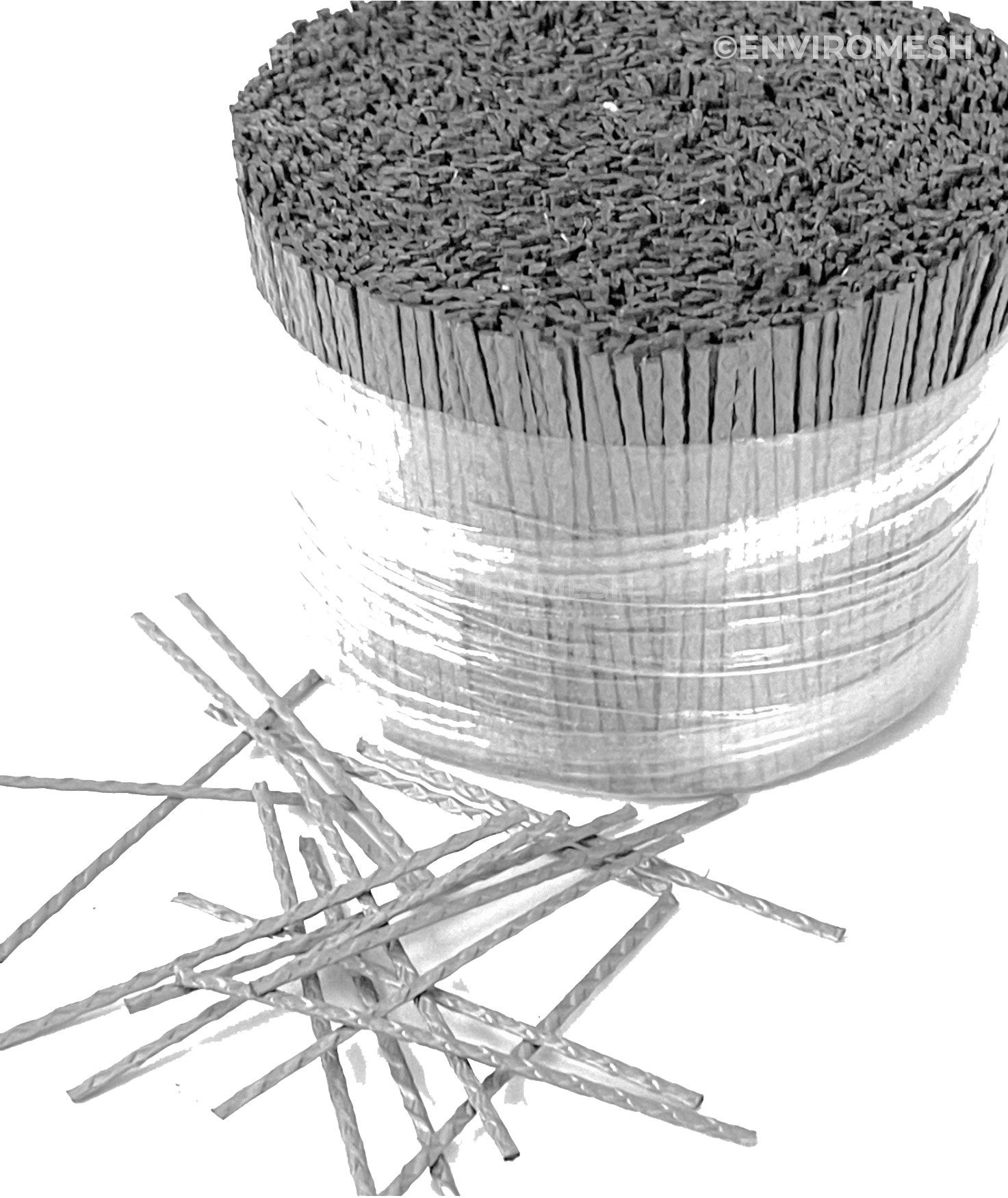

Small recycled plastic macro synthetic fibres are added to concrete to replace shrinkage steel.

eMesh completely replaces non-recycled plastic fibres or steel reinforcing mesh. 100% recycled plastic is a 90% reduction in CO2 compared to steel mesh.

While many Councils and Main Road Authorities already use virgin macro poly fibres in concrete in Australia, eMesh allows them to use 100% recycled plastic to achieve the same result.

eMesh is backed by research that took place at James Cook University conducted as part of a PhD study by Dr Shi Yin.

The fibres are manufactured in Australia.

Problem

Concrete shrinks during both its early and later life stages, so it’s vital that this contraction is allowed for. Soil uplift and/or subsidence, tree roots and soil pressure can cause rigid concrete to become unsupported or to crack.

The more traditional option to address this was the use of steel mesh, which offers restraint from cracking alongside construction joints that allow for shrinkage. But using steel is costly, draining on mineral resources, labour-intensive and presents safety hazards.

The next big advancement in concrete was the introduction of “macro poly fibre” about 15 years ago. While this was progressive at the time, the use of virgin macro poly fibres was not the best option for our environment.

Solution

eMesh controls the risk of shrinkage and cracking during both the early and later stages of concrete life. It offers the same level of reinforcement in concrete as non-recycled fibres, but it’s more cost-effective and environmentally friendly.

This allows private companies and government organisations using eMesh to achieve Green Ratings.

Next Generation

eMesh represents the next generation of innovation for standard virgin plastic fibres in concrete. eMesh is simpler, greener, safer and more cost-effective than current alternatives.

AUSTRALIAN

Made in Australia using Australian Plastic Waste.

100% Made and Owned in Australia

WINNER

The Australian Innovation Challenge Award

“Construction and Manufacturing Category.”

We Are Proud Members Of